Heaters can operate in a wide range of coolant temperatures:

Huge savings for new construction and renovation:

Quick heating and cooling of appliances

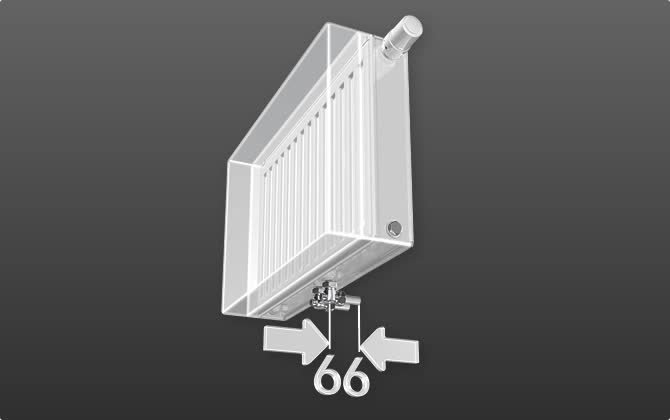

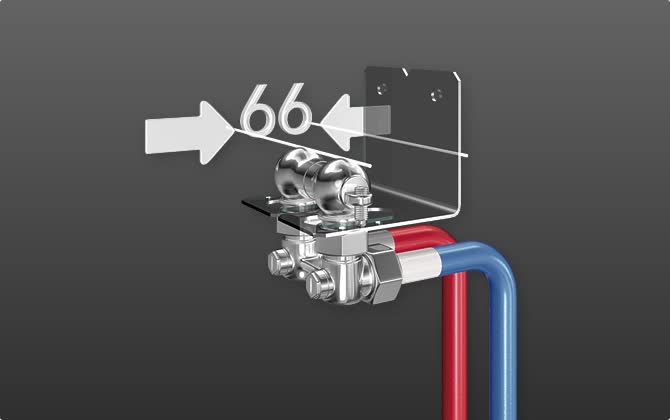

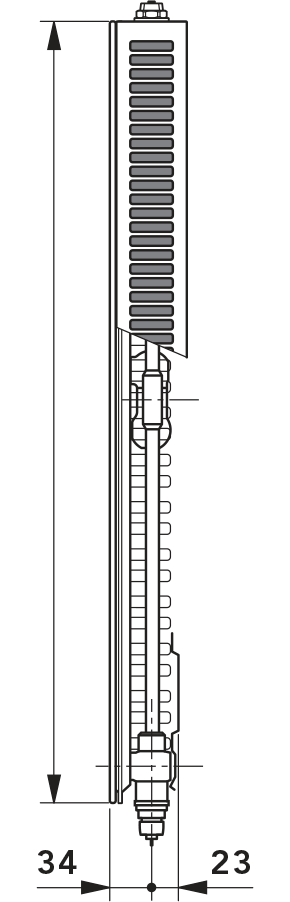

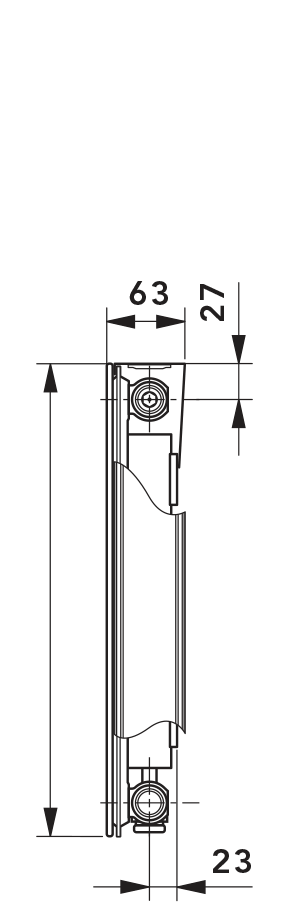

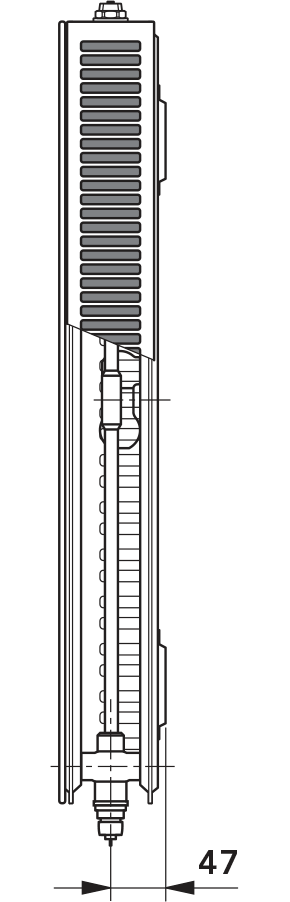

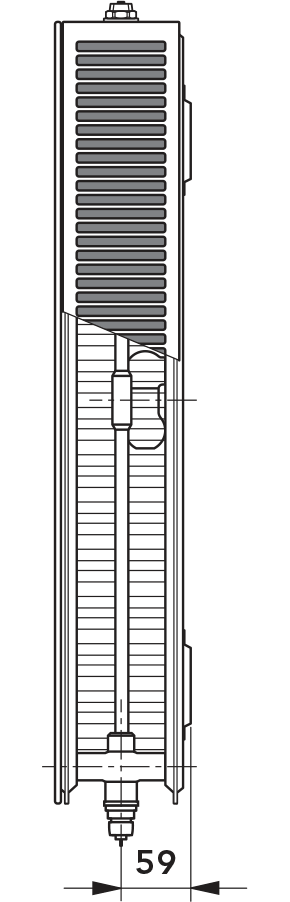

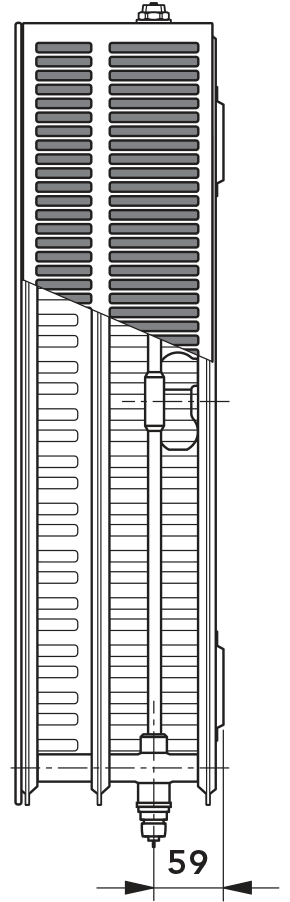

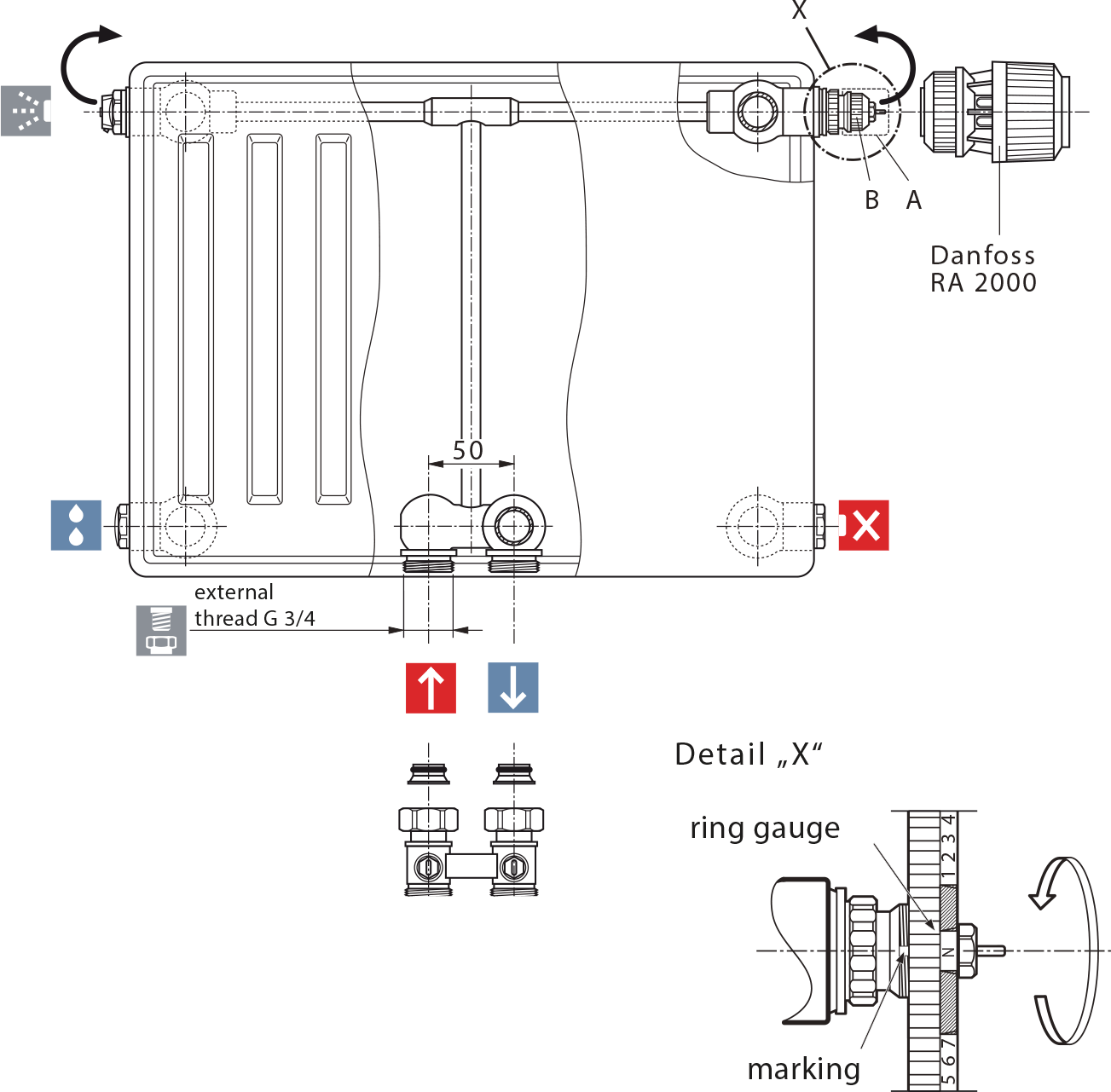

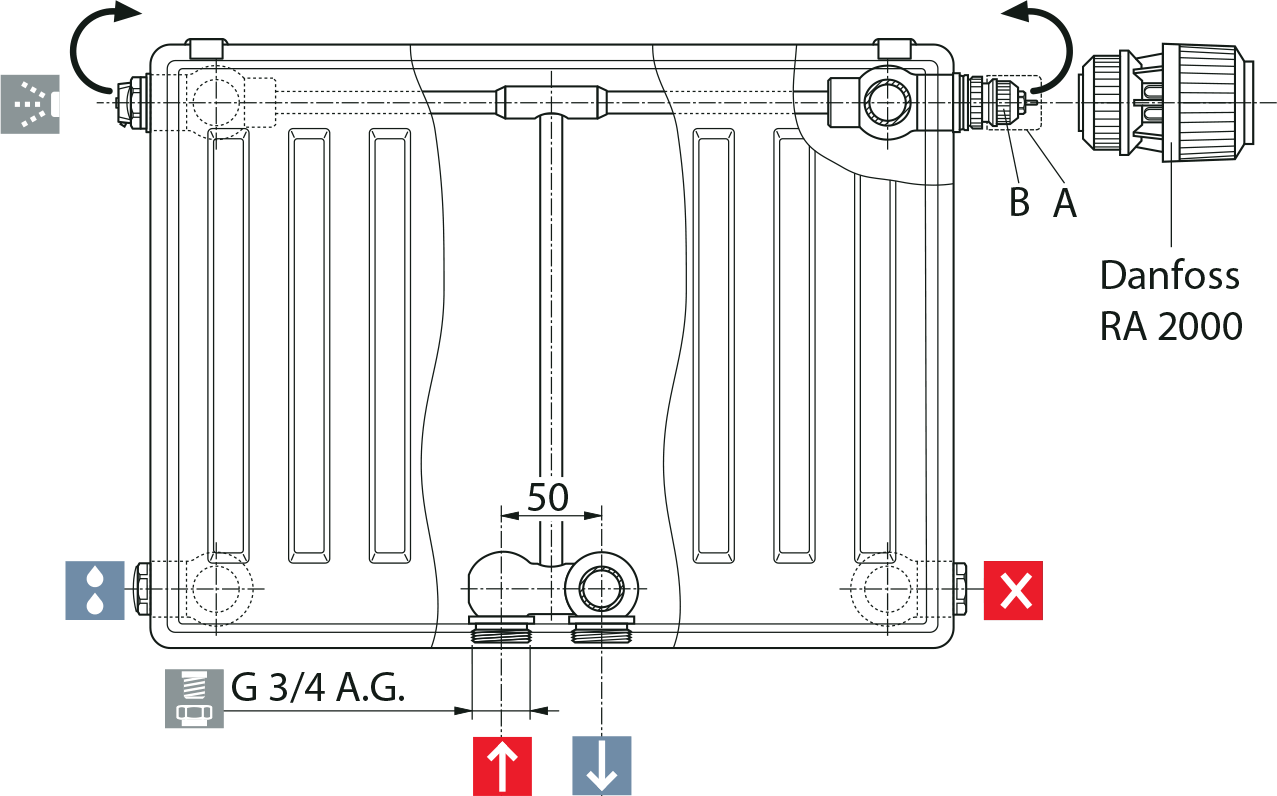

Bottom connection. Smooth face, high heat dissipation, built-in thermostatic valve.

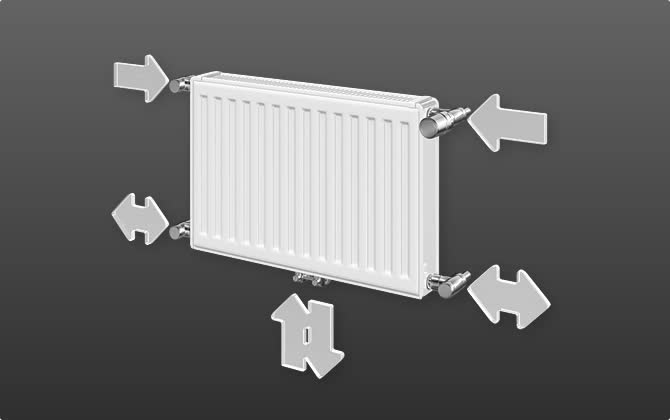

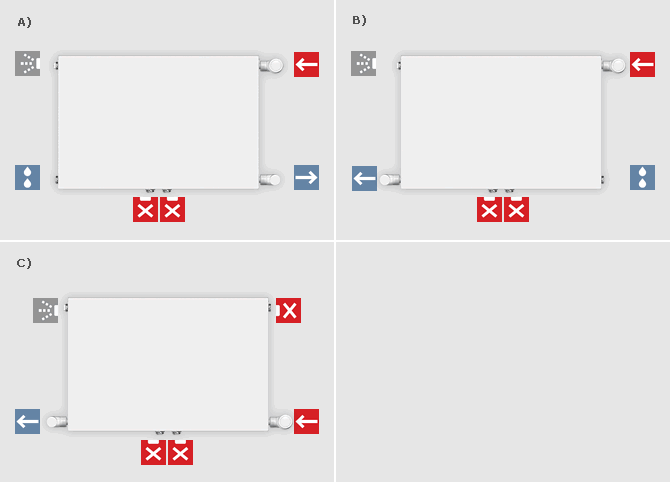

PLAN radiators are available for order with the following types of connections:

Connection to the heating system is possible through any of the 6 pipes.

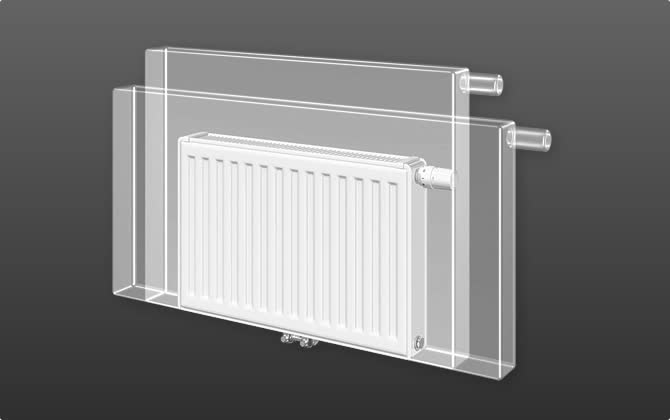

It is easy to change the size of the heatsink even after installation is completed.

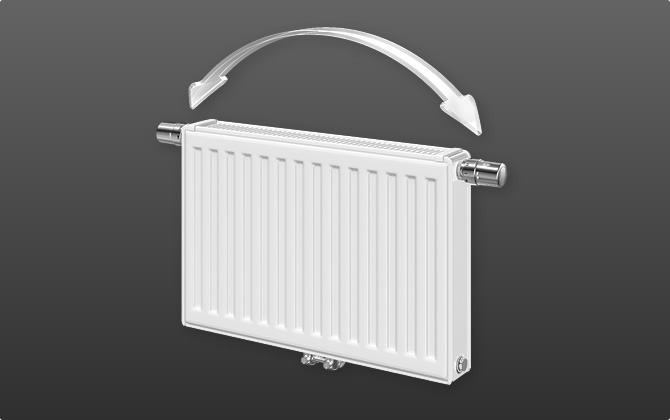

The thermostatic element can be installed on either side of the radiator.

It is possible to supply radiators without brackets on the rear wall of the radiator.

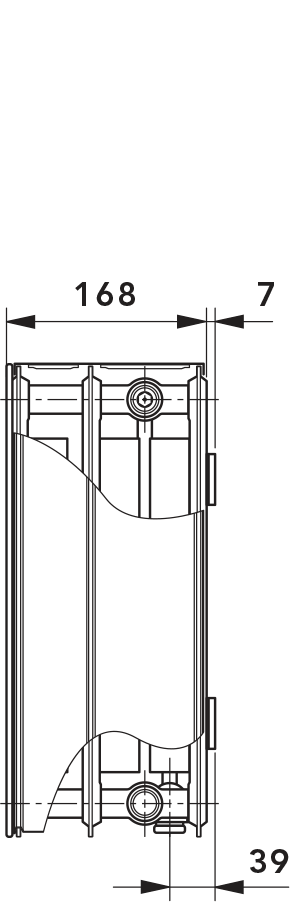

Standard wall distance for all types of radiators with central connection.

A bypass can be installed to test a heating system without a radiator.

| Height | 300 | 400 | 500 | 600 | 900 |

|---|---|---|---|---|---|

| Length | to 2400 | to 2600 | before 2000 | ||

| Depth | 63 | ||||

Pitch: total length starts at 400mm available in 200mm increments, optionally 520, 720, 920, 1120 and 1320mm.

| 2 heating panels with two convective grilles | |||||

|---|---|---|---|---|---|

| Height | 300 | 400 | 500 | 600 | 900 |

| length | to 2400 | to 3000 | before 2000 | ||

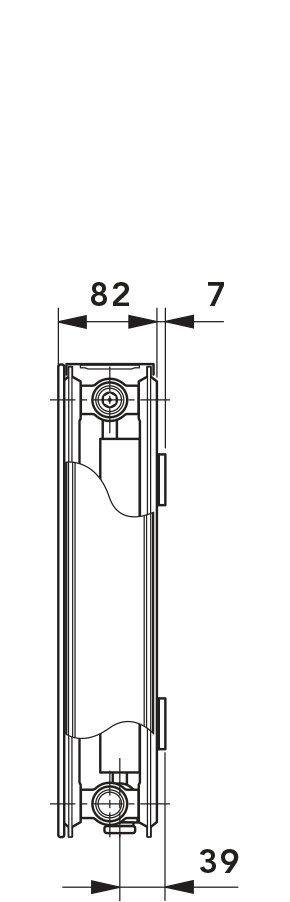

| Depth | 82 | ||||

Pitch: total length starts at 400mm available in 200mm increments, optionally 520, 720, 920, 1120 and 1320mm.

| 2 heating panels with two convective grilles | |||||

|---|---|---|---|---|---|

| Height | 300 | 400 | 500 | 600 | 900 |

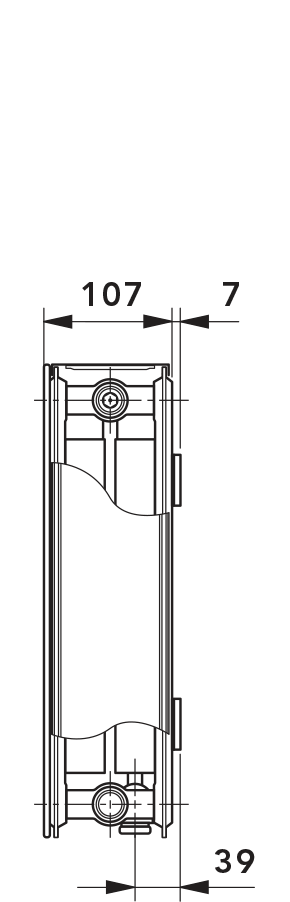

| length | to 3000 | before 2000 | |||

| Depth | 107 | ||||

Pitch: total length starts at 400mm available in 200mm increments, optionally 520, 720, 920, 1120 and 1320mm.

| 3 heating panels with three convective grilles | |||||

|---|---|---|---|---|---|

| Height | 300 | 400 | 500 | 600 | 900 |

| length | up to 3000 | to 2200 | before 1800 | ||

| Depth | 168 | ||||

Pitch: total length starts at 400mm available in 200mm increments, optionally 520, 720, 920, 1120 and 1320mm.

Warning:

When radiators T6-PLAN WITH CENTRAL BOTTOM CONNECTION are used as radiators with side connection ¾ plastic screw plugs must be replaced with nickel-plated brass plugs (optional). Available by part number: AZ0PL000C0002000. Additionally, the plastic parts of the special threaded connections must be removed.

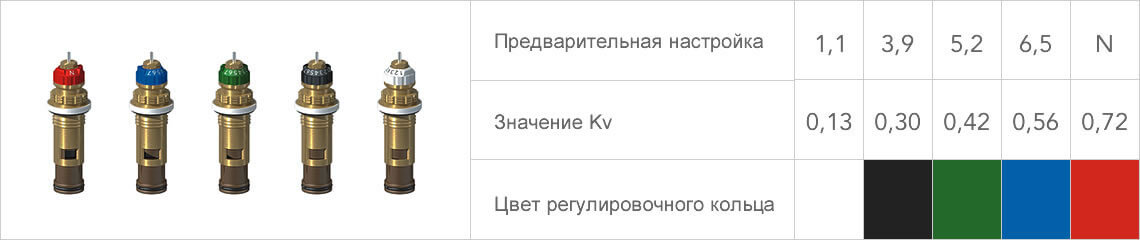

It is also possible to change the preset kv value of the thermostatic valve when the equipment is used under pressure.

Setup instructions:

VOGEL&NOOT valve radiators are made in accordance with the installation in a 2-pipe heating system. Each individual radiator has a pre-installed thermostatic valve, according to the radiator output. The set kv value is also indicated by the color of its cap.

Please note:

If it is necessary to adjust the kv value, it can be set arbitrarily on the thermostatic valve. Changing the installation location of the thermostatic valve from the left side to the right side, and vice versa, is possible at any time during operation. Radiators are supplied with protective plugs. After removing the protective plug (position A), the corresponding thermostatic head can be installed directly on the built-in thermostatic valve (position B): “RA 2000”,“RAW” by Danfoss, “VK” by Heimeier, “D” by Herz, “thera DA” by MNG and “UNI XD” by Oventrop.

In a one-pipe heating system, the built-in thermostatic valve must be set to N.

A protective plug is installed on the built-in thermostatic valve. After removing the protective plug, a standard RA thermostatic head can be installed on the thermostatic valve.

ATTENTION: When installing a radiator in a single-pipe heating system, it is necessary to provide for the installation of a connection unit with a bypass. If there is no bypass at the connection point, the heating system will not work.

Changing the built-in thermostatic valve from the right side to the left side, and vice versa, can be easily done at any time.

According to the EU regulation "On construction products" products used in construction, including radiators and convectors without a built-in heating element, must receive the CE marking on the basis of the harmonized product standards EN442, and have a "DECLARATION OF QUALITY DATA, Declaration of performance of construction products, declaration of performance" (DoP). The CE marking means that each individual product is manufactured in accordance with the requirements of the technological process for this type of product, established by the regulations regarding its production, testing and delivery. The regulation entered into force on July 1, 2013

RettigICC products carry the CE mark. The RettigICC`s "Declaration of Performance, Declaration of Performance, Declaration of Performance" by RettigICC, as well as documents detailing the performance of individual products (see appendices M and D) are available from in accordance with the provisions of the regulation "On construction products"; (See the attached RICC Statement of Performance in its latest edition and the documents it references.)

We will tell you in detail about our services, types of work and typical projects, calculate the cost and prepare an individual offer!